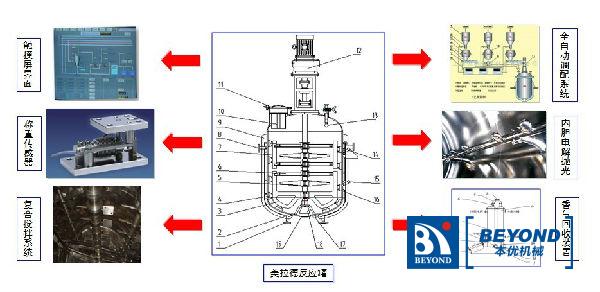

美拉德反应罐系统 Su Maillard reaction tank

本优机械美拉德反应罐主要包括反应罐体、搅拌系统(搅拌电机、搅拌减速器、刮板搅拌)及夹套加热系统等操作单元。投料孔为垂直方向,设计有放掉落网,下部出料口配备无滞留底阀,夹套进蒸汽口与冷凝水出口各为对称两个,温度探头分为上、中、下3个,在搅拌轴底部设计有可拆卸的扇形刮板。

The sumilard reaction tank mainly includes reaction tank body, mixing system (mixing motor, mixer reducer, scraper mixing), jacket heating system and other operating units. The feeding hole is vertical, and the design is equipped with a drop net. The lower outlet is equipped with a non stagnation bottom valve. The jacket inlet steam inlet and condensate outlet are symmetrical two, and the temperature probe is divided into the upper, middle and lower three, and a detachable fan scraper is designed at the bottom of the mixing shaft.

工作原理:

我司考虑到骨素美拉德反应是在较高温度下进行的热反应。美拉德反应罐使用前需要关闭无滞留底阀,之后加入经计量的液体物料。随后打开垂直投料口,加入美拉德反应需要的物料。加入之前,需要先开启搅拌电机及减速器,此时在搅拌轴的带动下,刮板搅拌、推进搅拌、框式搅拌全部随搅拌轴转动。刮板搅拌上安装的带弹簧的聚苯丙烯刮板对粘附在罐壁的物料进行刮壁,框式搅拌横梁与轴存在45。夹角形成向下推力。搅拌启动后再加入固体物料,防滑落网可以阻止较大的异物落入罐内。为了防止加入的固体物料沉积到搅拌轴支撑座下的死角内,底部扇形刮板能够将物料搅拌溶解。此时开启蒸汽,蒸汽通过夹套折流板和夹套封头对罐体内部物料加热,形成的冷凝水通过冷凝水口排出。为操作人员烫伤或热量散失,对罐体增加保温层。将垂直投料口关盖,进行反应。反应过程中观察探头的温度,调节搅拌速度和搅拌方向。反应完成后关闭蒸汽,打开无滞留底阀出料。出料完成后关闭搅拌,并开启清洗球对罐体内壁进行清洗,完成整个反应过程。

working principle:

We consider that the Maillard reaction of osteopontin is a thermal reaction at a higher temperature. Before using Maillard reaction tank, it is necessary to close the non stagnant bottom valve, and then add the measured liquid material. Then open the vertical feeding port and add the materials needed for Maillard reaction. Before adding, the mixing motor and reducer need to be turned on first. At this time, driven by the mixing shaft, the scraper mixing, push mixing and frame mixing all rotate with the mixing shaft. The polyphenylene propylene scraper with spring installed on the scraper stirrer scrapes the material adhered to the tank wall, and the frame stirring beam is 45 ° away from the shaft. The angle forms a downward thrust. Solid materials are added after the start of mixing to prevent large foreign matters from falling into the tank. In order to prevent the added solid material from depositing into the dead angle under the support seat of the stirring shaft, the bottom fan-shaped scraper can stir and dissolve the material. At this time, the steam is turned on, and the steam heats the materials inside the tank through the jacket baffle and jacket head, and the condensate water formed is discharged through the condensation nozzle. In order to prevent operators from scalding or heat loss, an insulating layer is added to the tank. Close the vertical feeding port for reaction. During the reaction, the temperature of the probe was observed, and the stirring speed and direction were adjusted. After the reaction, close the steam and open the non stagnant bottom valve for discharging. After discharging, turn off the mixing and start the cleaning ball to clean the inner wall of the tank to complete the whole reaction process.

美拉德反应罐优点:

1本系统机组全部采用优质不锈钢材料,符合食品卫生要求;

2连续流加,自动排料,实现连续可控美拉德反应,提高反应效率;

3复合搅拌系统解决了美拉德反应罐使用过程中不易清洗,产品易结焦等问题;

4香气回收装置有效避免了以往在骨素的美拉德反应过程中产生香味物质的损失。

Advantages of Maillard reaction tank:

1. All units of the system are made of high quality stainless steel, which meets the requirements of food hygiene;

2. Continuous feeding, automatic discharge, realize continuous and controllable Maillard reaction, improve reaction efficiency;

3. The compound stirring system solves the problems of difficult cleaning and coking of Maillard reaction tank in use;

4. The aroma recovery device effectively avoids the loss of aroma substances in the Maillard reaction of osteopontin.